Positive pressure Leak Tester service|coolant leak pressure tester : discounter Duct Leakage Testing – RETURN SYSTEM. Per ANSI/ASHRAE Standard 90.1-2010, “positive pressure leakage testing is acceptable for negative pressure ductwork”. Even so, you will see . VIP OF 35% OFF. WINTER SALE <3 . talk to me here! Free OF. PPV videos ;)

{plog:ftitle_list}

WEB22 de jul. de 2022 · Espero que tenha gostado do vídeo!Conteúdo Exclusivo 👉 https://linktr.ee/jacquelineoficial💋ME ENCONTRE NAS REDES SOCIAIS💋: https://instagram.com/jacquelin.

pressure leak testing equipment

grain moisture meter in lahore

Pressure testing services, including hydrostatic and pneumatic testing, verify the integrity and safety of your systems. With state-of-the-art equipment and experienced technicians, we guarantee accurate and reliable results across various industries.Cincinnati Test Systems provides innovative, high precision air leak detection technology. Request a quote on the leak test solution you need, or contact CTS to learn more. Contact .Duct Leakage Testing – RETURN SYSTEM. Per ANSI/ASHRAE Standard 90.1-2010, “positive pressure leakage testing is acceptable for negative pressure ductwork”. Even so, you will see .ATS fulfills clients' pressure leak testing needs by using industry-leading methods for detecting, locating, and quantifying even the smallest of leaks.

Leak testing is a Non-destructive Testing method or process where inspectors apply pressure to an object to locate defects that are causing leaks. Read More!

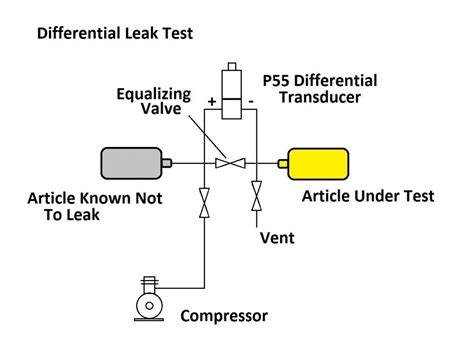

Vacuum and Pressure decay leak testing Basel, 27. February 2020 Presenter: Patrick Schlatter, WILCO AG, CH . –LFC, P, V (different types) –pressure curve / course –steps of the differential pressure test •Method selection •Equipment in process control •Applications of differential pressure . Using positive samples (capillaries .Per ANSI/ASHRAE Standard 90.1-2010, “positive pressure leakage testing is acceptable for negative pressure ductwork”. Even so, you will see specifications that may require return air or exhaust systems to be leak tested under a vacuum (negative pressure). To perform a proper duct leakage test under negative pressure using an ORIFLOW duct leakage tester, perform .*Not limited to the test pressure, the differential pressure sensor can use the minute differential pressure range, allowing for leak tests which are constantly highly precise. A pressure sensor corresponding to the range of the test .13.1 The test equipment (pressure measurement, tempera-ture measurement, and time measurement) must be appropri-ately calibrated and traceable to national or international standards. The accuracy of the method depends on the deter-mination of the test vessel volume as outlined in Annex A3. 13.2 Commercial pressure decay systems often use an

This standard leak rate value is frequently needed when issuing acceptance certificates but can also be of service when comparing leak rate values determined by . Positive pressure testing is, on the other hand, a technique commonly employed in tank engineering. When dealing with large containers and the long test periods they require for the .

Rob Siegel. In my book Just Needs a Recharge: The Hack Mechanic™ Guide to Vintage Air Conditioning, I make the case that those “A/C recharge .95” signs you see at service stations are perilously close to fraud. If a system needs to be recharged, it’s because the refrigerant has leaked out, so the leak first needs to be found, then needs to be fixed.vacuum method (sometimes known as an “outside-in leak”), where the direction of flow is into the test specimen (pressure inside the specimen being less than ambient pressure), and the b. positive pressure method (often referred to as the “inside-out leak”), where the fluid passes from inside the test specimen outward (pressure inside .The most common leak tester fittings are the Male Luer, Male Luer Lock, Female Luer Lock, 5 mm compression, 6 mm compression and the Staubli T. Different Leak Tester Fittings Pressure Range 0–30, 0–100 PSIG of Positive Pressure or 0-14.5 PSI of Vacuum

pressure leak test procedure

Vacuum and Pressure decay leak testing Venice, 22. March 2019 Presenter: Dr. Matthias Kahl, Head of R&D WILCO AG, CH. 2 Overview • Fundamentals of DP method –LFC, P, V (different types) –pressure curve / course . Using positive .LSSD-01 Leak and Seal Strength Tester is suitable for the quantitative measurement of sealing strength, heat sealing strength, binding strength, overall sealing performance, pressure resistance strength, cap body connection strength, bursting pressure and shedding strength. It is widely used in the soft package, plastic pilfer-proof caps, flexible pipes, etc.Overview of pressure decay leak testing. A Pressure decay leak test involves evaluating the drop in pressure on a transducer during a leak test. Under this method, the component under test is pressurized (filled with air until it reaches a set pressure), then isolated from the supply pressure. Using a pressure sensor, the pressure within the . The cuff leak test is used to predict risk of post-extubation stridor in intubated patients. Use and interpretation of the test needs to take into account the overall context of the patient's condition and the management implications . Positive End Expiratory Pressure (PEEP), Pulmonary Mechanics, Pressure Vs Time Graph, Pressure vs Volume .

Leak testing and pressure testing are often used synonymously. However, pressure testing is a misnomer when referring to leak testing of piping systems. By definition, a pressure test is the procedure performed on a relief valve to test its set-point pressure. . The initial service leak test is a process by which the test fluid is the fluid .

Find your pressure leak tester easily amongst the 158 products from the leading brands (JW FROEHLICH, CETA, ATEQ, .) on DirectIndustry, the industry specialist for your professional purchases. . Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a .The BLT bubble leak tester uses regulated pressure to test the integrity of sealed packs. Convenient, easy and quick to test single or multiple packs. . Contract testing of packaging materials; Service and Calibration; Spare .

Testing Capabilities. We ensure each assembly is leak-free through 100% testing. We test assemblies multiple ways: Bubble Leak Detection – Film Solution: A positive pressure is applied to the assembly. The pressure .Clients may request helium leak testing to assess the performance of a material or to analyze or evaluate component longevity. Helium is the preferred leak testing medium because technicians can detect and measure it at minute . 1.1 This practice describes a method for determining the leakage rate of a vessel subject to a positive pressure difference. The technique is based upon evaluation of the change of mass within the test object based on a pressure decay measurement. The pressure decay measurement uses the ideal gas equation of state and the measured pressures, temperatures, . How each leak test method works impacts which methods are best for different applications. Selecting the right air leak testing method for your application includes identifying your required leak rate, maximum test pressure, maximum temperature differences likely to occur during test, and desired cycle time. Part design and environmental .

Leak Testing - TQC's beginners and fundamentals guide to helium leak testing, what is it, why use it and the benefits of helium leak testing. . build up to the full test pressure in stages, build up to the full concentration, flush the mass spec with a gas with no helium present or pre-screen using an air decay technique before helium testing .Pressure decay is one of the most widely used methods of leak testing in manufacturing and is ideal for a sealed component with an access port. In this test, a product is attached to a leak tester and filled with air. Once pressurized, the air source is valved off and the pressure is allowed to settle.

The nitrogen leak test is carried out by filling the sealed system with nitrogen gas up to a specified test pressure. Monitoring devices are then used to observe any changes in pressure over a set period. A decrease in pressure would indicate a leak, and the rate of this pressure decay helps to quantify the leak rate. The Role of Positive Pressure Discover the effectiveness of pressure decay testing as a method for leak detection in this informative article. Explore the principles behind this technique, its applications in various industries, and the benefits it offers in terms of accuracy and efficiency. Gain insights into the process, equipment requirements, and best practices for conducting pressure decay tests, .P2:Test pressure after change (kPa) Q1:Leak rate before change (mL/min) Q2:Leak rate after change (mL/min) Leak rate ratio will differ from the theoretical equation in cases where there is a possibility of a change in the leak hole shape when the test pressure is changed, e.g. leaks in gasket seals. 4.Leak calibration in practiceRefer to Operation and Service Manual (TSI P/N 6004851) supplied . For positive pressure, low-flow testing, add the low-flow nozzle to the blower inlet if it is not installed per . Preparing PAN200 System for Air Duct Leak Testing 9 c. For negative pressure, high-flow testing, remove the low flow nozzle if it is installed.

Before LEAKAGE TESTING of the endoscope, PRECLEANING should be completed as described in the reprocessing manual. KEY Sink side Water . Pressure test Leakage Tester (MB-155) 1 Attach Leakage Tester (MB-155) 4 12 Q2022-0005 Issue 1 02/22. Created Date: 20220221124436Z .Test time: 30 seconds; Press F4 to continue and then just press auto test to begin. The 729 is setting the pressure 50 PSI and it is now going to settle for the time we set, and then start the leak test for about 30 seconds. Performing the pressure leak test. Now this is a great way of troubleshooting your pressure system.

Annie22love - Free Live Sex cams and Porn Chat | xHa.

Positive pressure Leak Tester service|coolant leak pressure tester